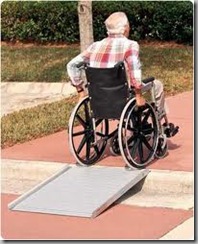

At first we bought a portable (fold-up) ramp. It was a little heavy, but it did the trick in many situations. Since we bought this aluminum ramp, newer designs have emerged that are lighter and easier to manage.

When we moved to Georgia, however, the house we wanted had too many steps and my confidence level had declined enough for me to know we needed ramps. The first ramp build was from the garage into the house. This worked great because it was wide enough to handle a wheelchair should I need it, but it also had handrails on both sides.

Later I wanted access to our rear deck, so we built a wraparound walkway that was actually a ramp. It is about forty feet long and slowly elevates to the height of the back deck. This walkway opened up a the back yard to me. I now have access to the deck from two rooms in the house and also from the driveway.

The front porch was another area that eventually became a problem. Even though it was only one step, once I was using a wheelchair that step became Mount Everest. A friend brought over a three foot by three foot grated aluminum pedestal ramp. This has become a lifesaver many times because it is portable enough to take to family and friends’ houses that do not have wheelchair access.

If you are considering building a ramp for your house, there are plenty of resources available on the internet as well as associations that provide brochures on the subject. “eHow”, for example has an excellent “how-to” guide for building several different types of ramps.

There are, however, some general rules that are good to know ahead of time.

- Building Permit: Always check with the building code office in your community and your homeowners association (if you have one) to see if a permit is required.

- Proper Dimensions:

- For a motorized wheelchair, the maximum slope is considered to be for every twelve inches (12”) in length, the ramp should not rise more than one inch (1”). For instance, if you need a ramp that extends from the ground to the top, at a height of 2 feet, you would multiply the height in inches (24 times 12) and come up with 288 inches. That equals 24 feet, so you would plan a minimum of 24 feet from the beginning of your ramp to the entrance.

- For a manual wheelchair or for walking, consider having a more gentle slope of 18” in length for every 1” rise.

- A good width is at least 42” wide with a four-inch curb along both side (planters can serve the same purpose and add a nice decoration). If you will need help walking up the ramp (someone beside you), the width should be 48-54”. If the width is a concern, consider the following as a minimum. After curbs or planters, and railings and handrails are installed the very minimum width should be no less than 36”.

- Design: Yes, you are building today, but planning for the future. At some time a wheelchair might be needed so always consider that possibility in your plans.

- Long ramps can be built in an ‘L’-shape or have a switchback in it.

- Long ramps are less attractive than short ones and always try to consider a location that is not as prominent as the front of the house if possible.

- Construction Materials: Poured concrete and pressure treated lumber are the best material and require the least maintenance.

- Pressure treated woods are good, but require annual maintenance. Concrete footings are best to minimize the woods contact with the ground.

- Concrete ramps are more expensive, but they have a longer life and require little maintenance.

- Products like ‘Trex’ (it has the appearance of wood and is coated with a nonslip surface) are a good choice because they require minimal maintenance.

- Landing Area: Plan at least five feet of landing space at both the top and bottom of the ramp.

- If the ramp changes direction (switchback or ‘L’-shaped) or is higher than three feet, include an intermediate landing if possible.

- Surface Materials:

- Use a nonslip deck paint on wood ramps.

- If using concrete, use a stiff brush (side to side strokes) while still wet to create better traction.

- Handrails: Railing should be on both sides and provide sturdy handrails between 36-38” high. Handrails must be continuous and secure as well as provide at least a 1½-inch space between the rail and a wall.

Another alternative when a ramp may not be practical is a wheelchair lift. It can be expensive and will probably require professional installation and maintenance. Some come with battery back-up in case of a power outage. Here is a link to a site to see examples.

ReplyDeletehttp://www.accessible-wheelchair-lifts.com/

Thank for the post..it help me a lot.

ReplyDelete